How it works

CO2 is pumped as a liquid. Once it reaches the reservoir, down-hole conditions cause it to become a super-critical fluid.

This phase change results in a significant increase in fluid volume, further extending fractures.

CO2 reduces the pH of water, which helps to break polymers and eliminate clay swelling in water sensitive formations.

Since CO2 remains a liquid throughout the wellbore portion of the treatment, it is suited to high fracture gradient reservoirs where additional hydrostatic pressure is required.

We customize our solutions.

Different completions have different needs. To meet deadlines in an economic and effective way that meets your requirements, we start with a deep understanding of your operations through full-service demand planning and product utilization forecasting.

The use of CO2 in well completions has proven to increase well productivity and the overall life of the well. We can help you plan an efficient and engineered solution.

Ferus has two CO2 plants located to service the Western Canadian Sedimentary Basin.

Between the plant and well site we have the transport, storage and on-site services to get you CO2 where you need it when you need it.

Tech Corner

Watch and subscribe to our series of technical video blogs to keep up to speed on the best ways to optimize your well production.

When CO2 is injected into an oil reservoir, it becomes soluble with the residual crude oil and light hydrocarbons. When CO2 dissolves in the oil it swells the oil and reduces its viscosity. This then enables the CO2 to displace the oil from the rock pores, pushing it towards a producing well.

An EOR alternative is to use CO2 in cyclic solvent injection (CSI), otherwise known as Huff ‘n’ Puff.

WHY IS CO2 USED FOR ENHANCED OIL RECOVERY (EOR)?

CO2 Huff n' Puff

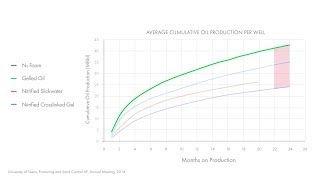

The injected CO2 dissolves in oil which is present in the reservoir and results in solution gas drive.

The CO2 reduces liquid viscosities and eliminates phase trapping caused by water, oil, or condensate.

A secondary drive is related to oil swelling in the presence of CO2.

The CO2 saturates formation water and displaces it from the near wellbore area, resulting in lower water production once the well is brought back on.

Watch our Tech V Talk about Huff n' Puff.